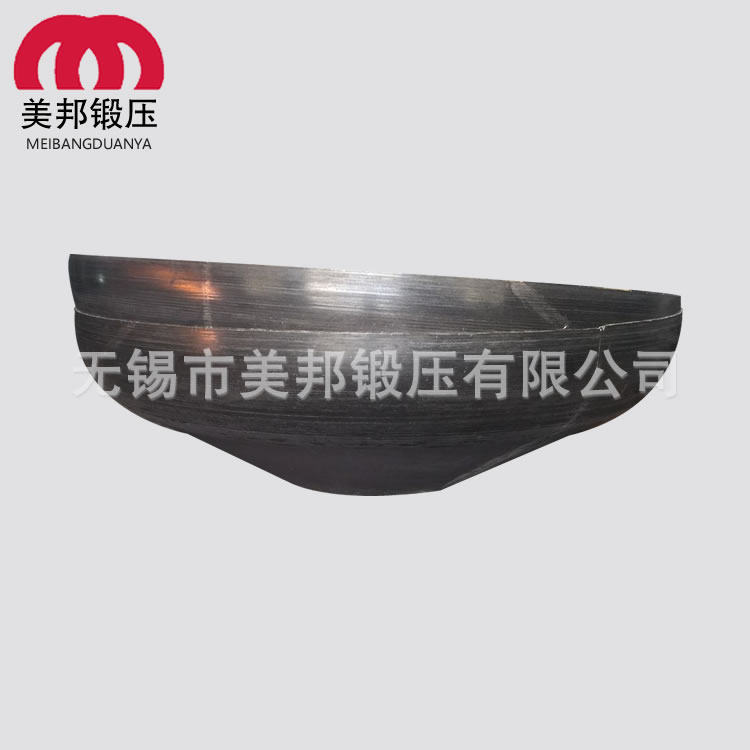

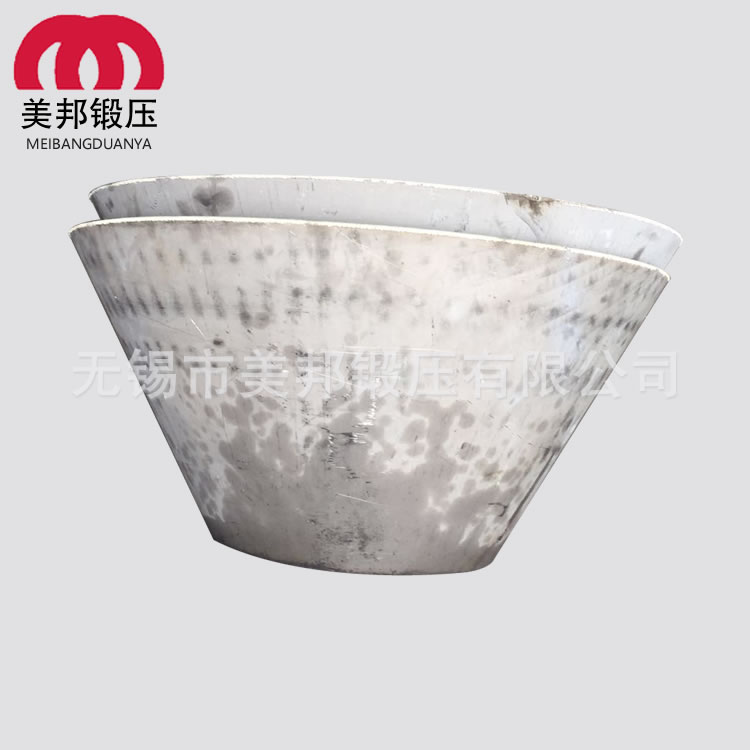

Product introduction

Under the action of internal pressure, the maximum film stress occurs at the large end of the main body of the conical head's cone. At the connection between the cone and the cylinder, due to geometric discontinuity and sudden changes in the radius of curvature, a large lateral thrust will be generated at this location, causing significant edge stress and making it prone to bending. Therefore, reinforcement is required. For the large end, the axial bending stress is the main controlling factor and it is a secondary stress, so the stress intensity is controlled internally. For the small end, since the stress conditions at the connection between the small end and the cylinder are mainly average circumferential tensile stress and average radial compressive stress, which belong to local film stress, the stress intensity can be controlled within. However, since the local film stress at this location may exceed the distribution range of the edge effect, for safety reasons, the stress intensity is controlled within. For the large end, under no circumstances shall the thickness of the reinforcing section be less than the thickness of the connected conical shell, and the length of the reinforcing section shall not be less than. The length of the reinforcing section of the cylinder shall not be less than. For the small end, under no circumstances shall the thickness of the reinforced section be less than the thickness of the connected conical shell, the length of the conical shell reinforced section shall not be less than, and the length of the cylindrical reinforced section shall not be less than.

The materials for manufacturing conical heads can be carbon steel, low alloy steel, composite plates, stainless steel, and non-ferrous metals such as copper, aluminum, and titanium. The standard implemented is GB/T 25198-2010. There are many varieties.

Our advantage