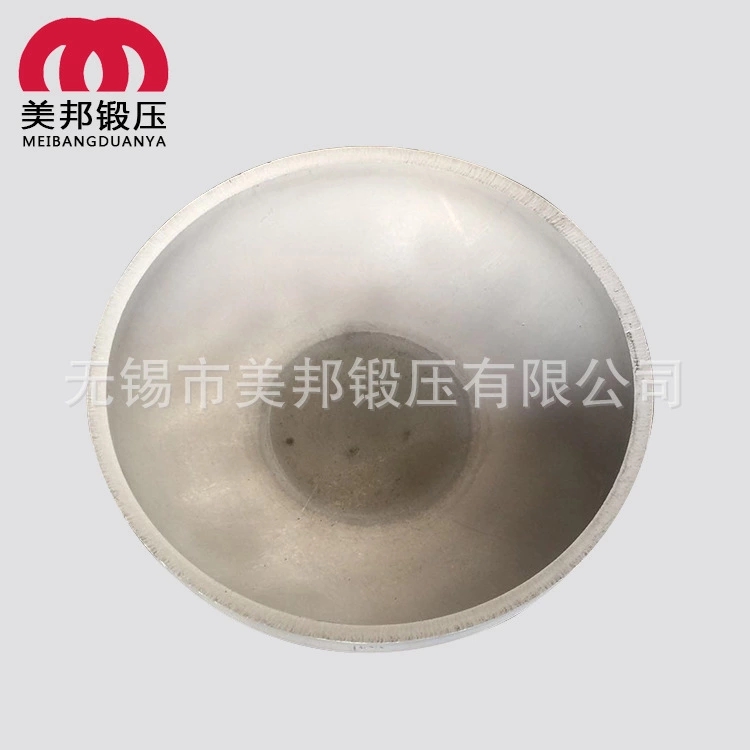

Product introduction

The magnitude of the organizational stress of stainless steel heads is related to factors such as the cooling rate of the workpiece in the martensitic transformation zone, its shape, and the chemical composition of the material. The ultimate result of the stress variation in the stainless steel head structure is tensile stress on the surface and compressive stress in the core, which is exactly the opposite of thermal stress. Practical experience has shown that during the heat treatment process of any workpiece, as long as there is phase transformation, thermal stress and organizational stress will occur. However, thermal stress has already occurred in the stainless steel head before the microstructure transformation, while the microstructure stress is generated during the microstructure transformation process. Throughout the cooling process, the combined effect of thermal stress and microstructure stress results in the actual stress existing in the workpiece.

The application scope of stainless steel heads includes industries such as petroleum, electronics, heating, chemical engineering, medicine, sewage treatment, light textile, food, machinery, construction, nuclear power, aerospace, pressure vessels, and military industry.

Our advantage